Double Nozzle Types Conformal Coating Machine with 0.02mm Precision

Conformal Coating Machine Application:

PCBA surface coating, dam process, coating solder mask, DIP components fixing.

Conformal Coating Machine Technical Parameter

Model | YSVC-3L |

External Size L*W *H | 1010*1360*1675mm(L*W*H) |

Weight | 500KG |

Control Mode | IPC+control card |

Software | YS software+Windows |

Programming | Teaching box |

Axis | X,Y,Z |

Drive | Servo motor +ball screw |

Max. move speed | 800mm/s |

Coating scope | L580*W580mm |

Max .PCB height | up 90 down 90mm |

Rotation angle | ±180º |

Positioning accuracy | 0.02mm |

Repeat accuracy | 0.02mm |

Conveyor quantity | 1 |

Width adjusting mode | auto |

Width adjust speed | 250mm/min |

Conveyor height | 900±20mm |

Conveyor speed | 2-5mm/min |

Conveyor direction | L-R(R-L optional) |

PCB edge space | ≧5mm |

Conveyor motor power | DC24V 69W |

Communication port | SMEMA port |

Nozzle quantity | 2 sets |

Nozzle type | pin type spray nozzle,film nozzle |

Tilt angle | 0~35º |

Single coating width | 2-30mm(According to the selected value) |

Material volume | 5L |

Draft capacity | 15 m3 /min |

Power supply | AC220V 50/60Hz |

Total power | 2.2KW |

Pressure | 0.4Mpa |

Programming panel | Standard |

Material Detection | Standard |

Camera location | Standard |

Clamp device | Standard |

Bar code | Standard |

UPS | Standard |

Waste recycling | Standard |

Conformal Coating Machine Features:

1.Motion controller use computer+,WINDOWS operating system, failure alarming menu

2.Available by manual teaching programming which is easy and quick

3.Integral steel moving platform, to ensure the smooth running

4.X, Y, Z three-axis motion

5.Servo motor+ball screw drive

6.Run precision of 0.02mm,automatically eliminate difference

7.Nozzles automatic cleaning device

8.Special aluminum alloy rail and stainless steel conveyor chain

9.Independent material container

10.Equip with gas collection, exhausting devices

11.SMEMA port to connect with other devices

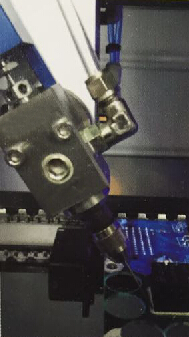

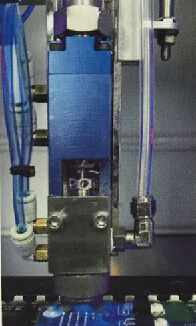

Nozzle Option and Function:

| Tilt for dispensing |  |

Can equipped with 2 sets of nozzle. |

Components fixing, |

| ||||

|

Automatic solbent after purging |

Double Nozzle Types Conformal Coating Machine with 0.02mm Precision

Conformal Coating Machine Application:

PCBA surface coating, dam process, coating solder mask, DIP components fixing.

Conformal Coating Machine Technical Parameter

Model | YSVC-3L |

External Size L*W *H | 1010*1360*1675mm(L*W*H) |

Weight | 500KG |

Control Mode | IPC+control card |

Software | YS software+Windows |

Programming | Teaching box |

Axis | X,Y,Z |

Drive | Servo motor +ball screw |

Max. move speed | 800mm/s |

Coating scope | L580*W580mm |

Max .PCB height | up 90 down 90mm |

Rotation angle | ±180º |

Positioning accuracy | 0.02mm |

Repeat accuracy | 0.02mm |

Conveyor quantity | 1 |

Width adjusting mode | auto |

Width adjust speed | 250mm/min |

Conveyor height | 900±20mm |

Conveyor speed | 2-5mm/min |

Conveyor direction | L-R(R-L optional) |

PCB edge space | ≧5mm |

Conveyor motor power | DC24V 69W |

Communication port | SMEMA port |

Nozzle quantity | 2 sets |

Nozzle type | pin type spray nozzle,film nozzle |

Tilt angle | 0~35º |

Single coating width | 2-30mm(According to the selected value) |

Material volume | 5L |

Draft capacity | 15 m3 /min |

Power supply | AC220V 50/60Hz |

Total power | 2.2KW |

Pressure | 0.4Mpa |

Programming panel | Standard |

Material Detection | Standard |

Camera location | Standard |

Clamp device | Standard |

Bar code | Standard |

UPS | Standard |

Waste recycling | Standard |

Conformal Coating Machine Features:

1.Motion controller use computer+,WINDOWS operating system, failure alarming menu

2.Available by manual teaching programming which is easy and quick

3.Integral steel moving platform, to ensure the smooth running

4.X, Y, Z three-axis motion

5.Servo motor+ball screw drive

6.Run precision of 0.02mm,automatically eliminate difference

7.Nozzles automatic cleaning device

8.Special aluminum alloy rail and stainless steel conveyor chain

9.Independent material container

10.Equip with gas collection, exhausting devices

11.SMEMA port to connect with other devices

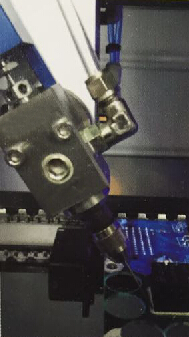

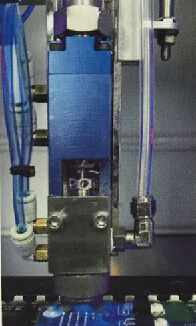

Nozzle Option and Function:

| Tilt for dispensing |  |

Can equipped with 2 sets of nozzle. |

Components fixing, |

| ||||

|

Automatic solbent after purging |

High Quality 3D laser marking machine For SMT Production Line YSL-3D-F30CY/50CY/100CY/ 200/CY

High Quality In-line flight marker For SMT Production Line YSL-F20CY/F30CY/F50CY

High Quality Pulse laser welding machine For SMT Production Line

High Quality Ultraviolet laser marking machine For SMT Production Line

High Quality Multi-function automatic laser welding machine For SMT Production Line

High Quality Fiber Laser Marking Machine For SMT Production Line

Full pneumatic steel mesh cleaning machine YSL-600 L1000*W700*H1730( mm )

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Environmentally Friendly Water-Based Online PCBA Cleaning Machine YSL-600-500

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Split selective wave soldering machine YS-320S For SMT Production LIine

High Quality Desktop selective wave soldering YS-E320 For SMT Production LIine

High Quality Integrated selective wave soldering YS-450Y / YS-450YT

High Quality Integrated selective wave soldering YS-320Y/ YS-320YT