Equipment performance parameters

| Model | YSL-LED |

| PCB Max Size | 890X510mm (Two-stage support 1200-1500mm) |

| PCB Min Size | 50X60mm |

| PCB Thickness | 1~6mm |

| Transport Height | 900 ± 40mm |

| Transport Direction | L-R / R-L |

| Product weight | ≤5KG |

| Conveyor Edge Distance | ≥9mm |

| Bottom Of Compinent Height | ≤10mm |

| Lifter Methhod | Side Lifter |

| Conveyor Stage | Two-section transport rail |

| I/O lnterface | SMEMA |

| Cleaning System | Vacuum cleaning Glue |

| CCD FOV | 13x10mm |

| visual system | CCD Vision Positioning System |

| Machine Specifications | |

| Position Accuracy | ±50μm@3sigma |

| Repeat Position Accuracy | ±25μm@3sigma |

| Operating system | Windows 7 |

| Air supply | 4~6 Kgf/cm2 |

| Power supply | AC:220±10%, 50/60HZ ,1.5KW |

| Control Method | PC Control |

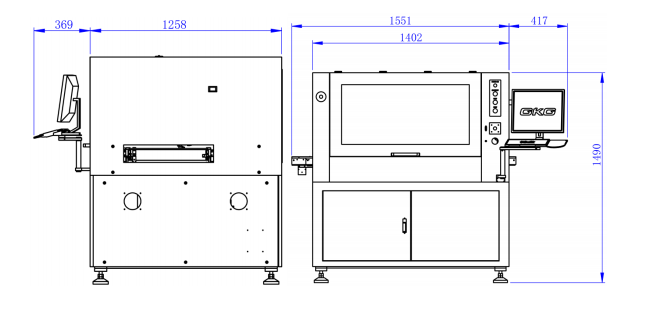

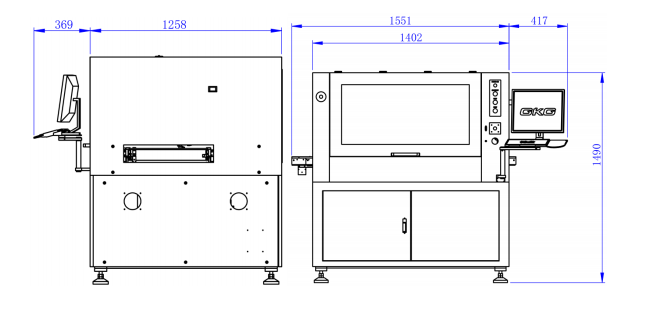

| Machine Dimensions | 1600(L) x 1258(W) x 1490(H)mm |

| Machine Weight | Approx: 1000Kg |

Functional configuration

| The standard configuration | Air pressure stabilization device | option configuration | Microbalance |

| Vacuum cleaning device | wipe system | ||

| Low hydraulic level detection | Scan the code online | ||

| XYZ axis calibration platform | Dual valve synchronization | ||

| head heating | MES system | ||

| Pneumatic valve | Piezo valve |

Dimensions and Appearance

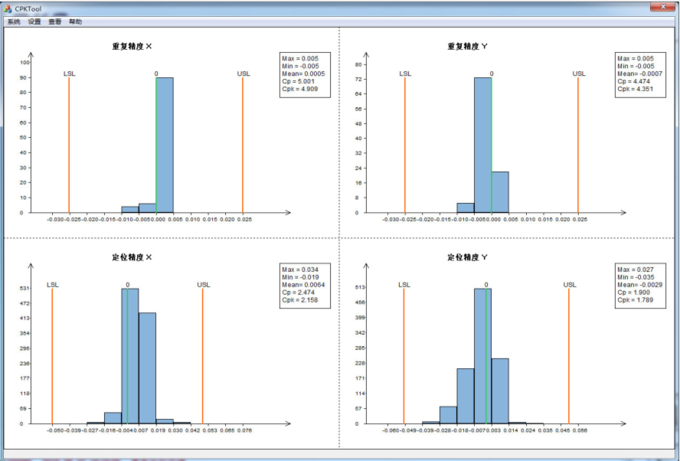

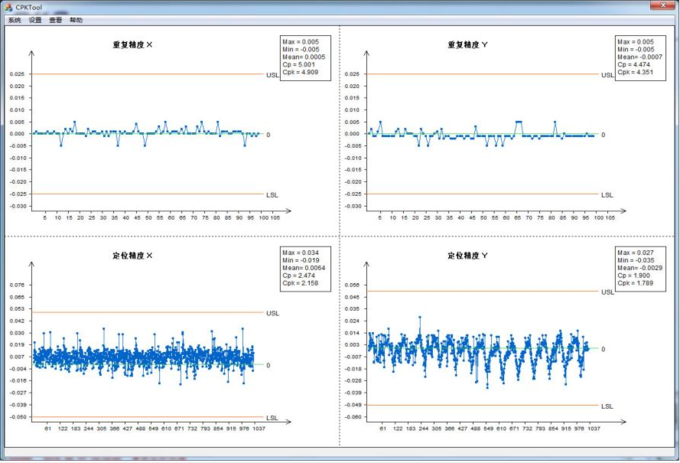

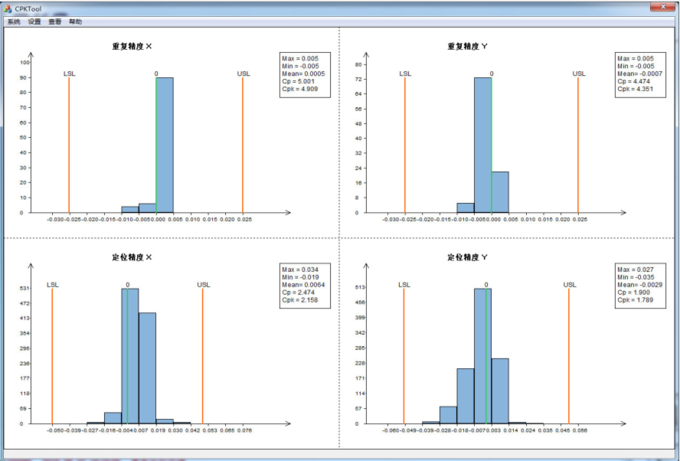

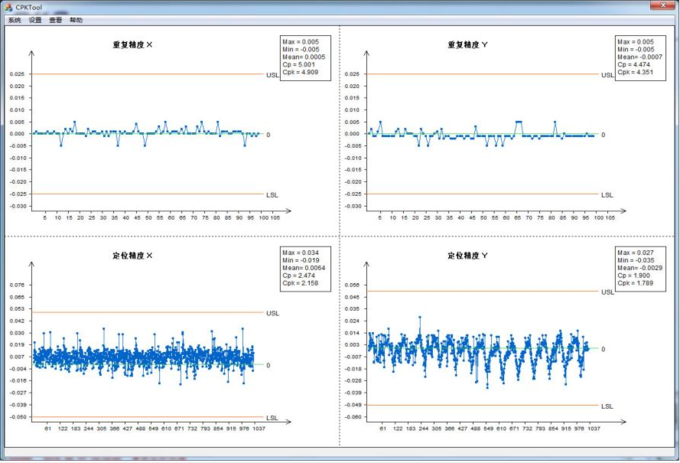

Testing report

| Test items | Repeat accuracy X | Repeat accuracy Y | Positioning accuracy X | Positioning accuracy Y |

| Specification | ―25μm~25μm | ―50μm~50μm | ||

| standard | 3.335 | 3.593 | 2.692 | 1.995 |

| CPK measured value | passed | passed | passed | passed |

Repeatability

Test method: The machine simulates production by itself, generates CPK data, CPK test software reads and analyzes the results, and generates graphics

Test speed: CCD X: 800mm/s

CCD Y: 800mm/s

Image acquisition delay: 110ms

Transport speed: 20mm/s

Test environment: machine level

Temperature: 24℃

Humidity: 60%

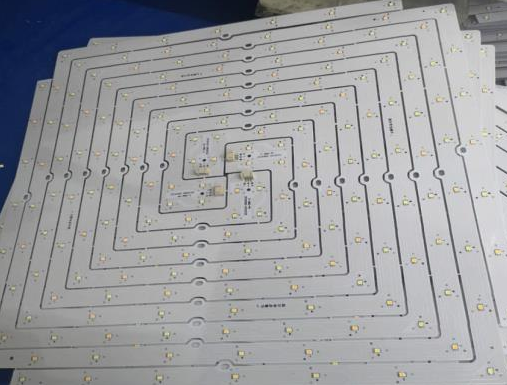

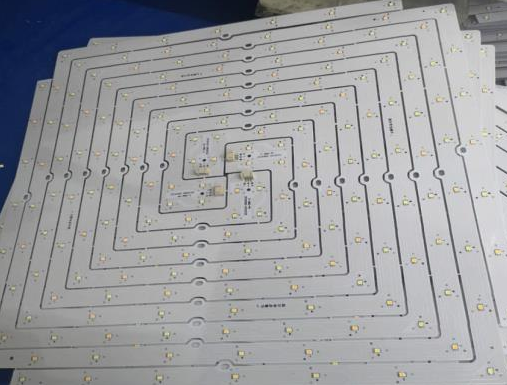

Application field

Equipment performance parameters

| Model | YSL-LED |

| PCB Max Size | 890X510mm (Two-stage support 1200-1500mm) |

| PCB Min Size | 50X60mm |

| PCB Thickness | 1~6mm |

| Transport Height | 900 ± 40mm |

| Transport Direction | L-R / R-L |

| Product weight | ≤5KG |

| Conveyor Edge Distance | ≥9mm |

| Bottom Of Compinent Height | ≤10mm |

| Lifter Methhod | Side Lifter |

| Conveyor Stage | Two-section transport rail |

| I/O lnterface | SMEMA |

| Cleaning System | Vacuum cleaning Glue |

| CCD FOV | 13x10mm |

| visual system | CCD Vision Positioning System |

| Machine Specifications | |

| Position Accuracy | ±50μm@3sigma |

| Repeat Position Accuracy | ±25μm@3sigma |

| Operating system | Windows 7 |

| Air supply | 4~6 Kgf/cm2 |

| Power supply | AC:220±10%, 50/60HZ ,1.5KW |

| Control Method | PC Control |

| Machine Dimensions | 1600(L) x 1258(W) x 1490(H)mm |

| Machine Weight | Approx: 1000Kg |

Functional configuration

| The standard configuration | Air pressure stabilization device | option configuration | Microbalance |

| Vacuum cleaning device | wipe system | ||

| Low hydraulic level detection | Scan the code online | ||

| XYZ axis calibration platform | Dual valve synchronization | ||

| head heating | MES system | ||

| Pneumatic valve | Piezo valve |

Dimensions and Appearance

Testing report

| Test items | Repeat accuracy X | Repeat accuracy Y | Positioning accuracy X | Positioning accuracy Y |

| Specification | ―25μm~25μm | ―50μm~50μm | ||

| standard | 3.335 | 3.593 | 2.692 | 1.995 |

| CPK measured value | passed | passed | passed | passed |

Repeatability

Test method: The machine simulates production by itself, generates CPK data, CPK test software reads and analyzes the results, and generates graphics

Test speed: CCD X: 800mm/s

CCD Y: 800mm/s

Image acquisition delay: 110ms

Transport speed: 20mm/s

Test environment: machine level

Temperature: 24℃

Humidity: 60%

Application field

High Quality 3D laser marking machine For SMT Production Line YSL-3D-F30CY/50CY/100CY/ 200/CY

High Quality In-line flight marker For SMT Production Line YSL-F20CY/F30CY/F50CY

High Quality Pulse laser welding machine For SMT Production Line

High Quality Ultraviolet laser marking machine For SMT Production Line

High Quality Multi-function automatic laser welding machine For SMT Production Line

High Quality Fiber Laser Marking Machine For SMT Production Line

Full pneumatic steel mesh cleaning machine YSL-600 L1000*W700*H1730( mm )

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Environmentally Friendly Water-Based Online PCBA Cleaning Machine YSL-600-500

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Split selective wave soldering machine YS-320S For SMT Production LIine

High Quality Desktop selective wave soldering YS-E320 For SMT Production LIine

High Quality Integrated selective wave soldering YS-450Y / YS-450YT

High Quality Integrated selective wave soldering YS-320Y/ YS-320YT