Features:

1. Independent research and development of electromagnetic pump

2. Adopt roller conveying system to increase welding space

3. Modular design, easy to maintain

4. Display the welding status in the whole process

| Parameter | Name | Specification |

| Body parameters | Device Dimensions | 1435(L)*1800(W)*1670(H) |

| Equipment weight (KG) | 1050 | |

| Maximum PCB board size | 510(L)*450(W) | |

| Minimum PCB board size | 120(L)*50(W) | |

| PCB top clearance | 120 | |

| PCB bottom clearance | 60 | |

| PCB process side | ≥3 | |

| Conveyor belt height above ground | 900±20 | |

| PCB transfer speed | 0.2-10 | |

| PCB weight (KG) | ≤5 | |

| PCB thickness (including fixture) | 1-6 | |

| Adjustable range of conveyor belt | 50-450 | |

| Conveyor belt width adjustment method | Electric | |

| PCB transfer direction | Left to right | |

| Air intake pressure | 0.6 | |

| Nitrogen supply | Provided by customer | |

| Nitrogen inlet pressure | 0.6 | |

| Nitrogen consumption | 1.5 | |

| Required nitrogen purity | >99.999 | |

| Voltage | 380 | |

| Frequency | 50/60 | |

| Maximum power consumption | <28 | |

| Maximum current | <56 | |

| Ambient temperature | ||

| Machine noise | <65 | |

| Communication Interface | SMEMA | |

| Welding system | Welding X-axis maximum travel | 510 |

| Maximum travel of welding Y axis | 450 | |

| Welding Z axis maximum travel | 60 | |

| Minimum Nozzle Outer Diameter | 5.5 | |

| Nozzle inner diameter | 2.5-10 | |

| Maximum crest height | 5 | |

| Tin furnace capacity | Approx.13kg(Sn63Pb)/ Approx.12kg(lead-free) | |

| Maximum Soldering Temperature | 330 | |

| Tin furnace heating power | 1.15 | |

| Preheating system | Preheat temperature range | <200 |

| Heating power | 6 | |

| Heating method | Hot air |

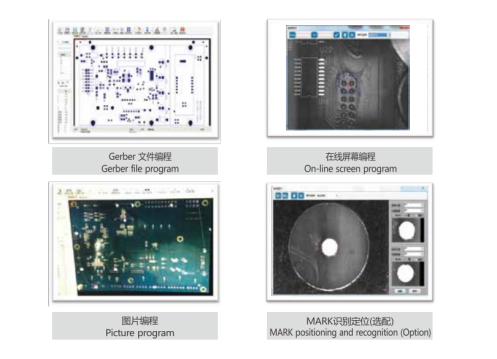

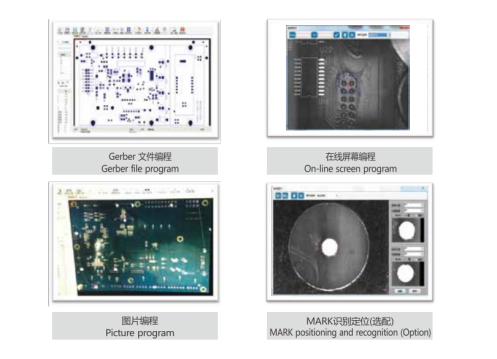

Fast and convenient programming system

Features and advantages:

1. Three programming methods to choose from

2. Support offline programming

3. Different welding parameters are available for each welding point

4. Process data recording

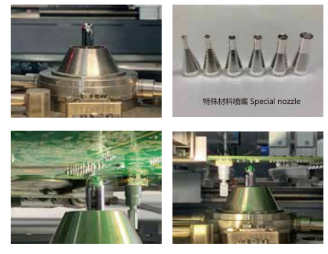

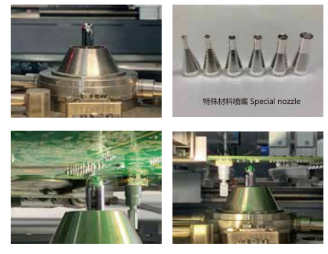

Stable and high-quality welding----welding module

Features:

1. The crest is stable

2. The nozzle is easy to remove and replace

3. High quality nozzle (can be used for 3 months)

4. Small footprint

5. Energy saving

6. Fast line change

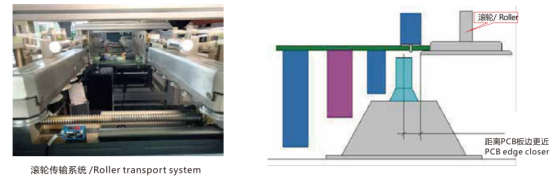

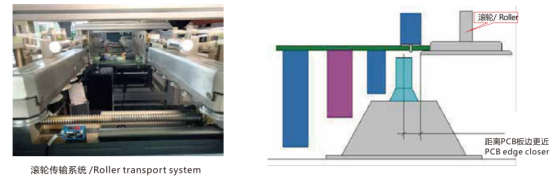

Transmission system----transmission track

The transmission system adopts roller conveying, which increases the welding space and is more conducive to the welding of components close to the edge of the board.

Solutions for high productivity

1. Modular design to meet the requirements of flexibility and high production capacity

2. Suitable for double splicing, double the production capacity

3. Occasions where two specifications of nozzles to meet the needs of imposition are completed

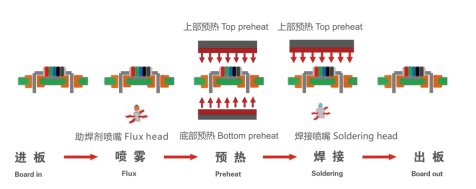

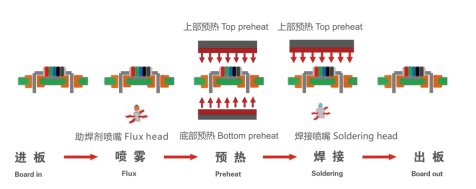

Selective soldering process

Welding process:

1. Transfer the PCB board to the designated location

2. The electromagnetic pump is welded according to the programmed path, and the top hot air is preheated at the same time

3. PCB outgoing

Basic structure module

Using an electromagnetic pump, compared with a mechanical pump, the electromagnetic pump has stable wave peaks during operation, no mechanical wear of the movement, and produces very little waste. In addition, the welding module adopts a high-precision motion system to ensure the accuracy of the welding process. , The colleague cooperates with the special process, which can greatly eliminate the phenomenon of tin connection. In terms of user experience, it provides welding monitoring cameras and automatic detection of wave height, which greatly improves the user experience.

Features:

1. Independent research and development of electromagnetic pump

2. Adopt roller conveying system to increase welding space

3. Modular design, easy to maintain

4. Display the welding status in the whole process

| Parameter | Name | Specification |

| Body parameters | Device Dimensions | 1435(L)*1800(W)*1670(H) |

| Equipment weight (KG) | 1050 | |

| Maximum PCB board size | 510(L)*450(W) | |

| Minimum PCB board size | 120(L)*50(W) | |

| PCB top clearance | 120 | |

| PCB bottom clearance | 60 | |

| PCB process side | ≥3 | |

| Conveyor belt height above ground | 900±20 | |

| PCB transfer speed | 0.2-10 | |

| PCB weight (KG) | ≤5 | |

| PCB thickness (including fixture) | 1-6 | |

| Adjustable range of conveyor belt | 50-450 | |

| Conveyor belt width adjustment method | Electric | |

| PCB transfer direction | Left to right | |

| Air intake pressure | 0.6 | |

| Nitrogen supply | Provided by customer | |

| Nitrogen inlet pressure | 0.6 | |

| Nitrogen consumption | 1.5 | |

| Required nitrogen purity | >99.999 | |

| Voltage | 380 | |

| Frequency | 50/60 | |

| Maximum power consumption | <28 | |

| Maximum current | <56 | |

| Ambient temperature | ||

| Machine noise | <65 | |

| Communication Interface | SMEMA | |

| Welding system | Welding X-axis maximum travel | 510 |

| Maximum travel of welding Y axis | 450 | |

| Welding Z axis maximum travel | 60 | |

| Minimum Nozzle Outer Diameter | 5.5 | |

| Nozzle inner diameter | 2.5-10 | |

| Maximum crest height | 5 | |

| Tin furnace capacity | Approx.13kg(Sn63Pb)/ Approx.12kg(lead-free) | |

| Maximum Soldering Temperature | 330 | |

| Tin furnace heating power | 1.15 | |

| Preheating system | Preheat temperature range | <200 |

| Heating power | 6 | |

| Heating method | Hot air |

Fast and convenient programming system

Features and advantages:

1. Three programming methods to choose from

2. Support offline programming

3. Different welding parameters are available for each welding point

4. Process data recording

Stable and high-quality welding----welding module

Features:

1. The crest is stable

2. The nozzle is easy to remove and replace

3. High quality nozzle (can be used for 3 months)

4. Small footprint

5. Energy saving

6. Fast line change

Transmission system----transmission track

The transmission system adopts roller conveying, which increases the welding space and is more conducive to the welding of components close to the edge of the board.

Solutions for high productivity

1. Modular design to meet the requirements of flexibility and high production capacity

2. Suitable for double splicing, double the production capacity

3. Occasions where two specifications of nozzles to meet the needs of imposition are completed

Selective soldering process

Welding process:

1. Transfer the PCB board to the designated location

2. The electromagnetic pump is welded according to the programmed path, and the top hot air is preheated at the same time

3. PCB outgoing

Basic structure module

Using an electromagnetic pump, compared with a mechanical pump, the electromagnetic pump has stable wave peaks during operation, no mechanical wear of the movement, and produces very little waste. In addition, the welding module adopts a high-precision motion system to ensure the accuracy of the welding process. , The colleague cooperates with the special process, which can greatly eliminate the phenomenon of tin connection. In terms of user experience, it provides welding monitoring cameras and automatic detection of wave height, which greatly improves the user experience.

High Quality 3D laser marking machine For SMT Production Line YSL-3D-F30CY/50CY/100CY/ 200/CY

High Quality In-line flight marker For SMT Production Line YSL-F20CY/F30CY/F50CY

High Quality Pulse laser welding machine For SMT Production Line

High Quality Ultraviolet laser marking machine For SMT Production Line

High Quality Multi-function automatic laser welding machine For SMT Production Line

High Quality Fiber Laser Marking Machine For SMT Production Line

Full pneumatic steel mesh cleaning machine YSL-600 L1000*W700*H1730( mm )

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Environmentally Friendly Water-Based Online PCBA Cleaning Machine YSL-600-500

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Split selective wave soldering machine YS-320S For SMT Production LIine

High Quality Desktop selective wave soldering YS-E320 For SMT Production LIine

High Quality Integrated selective wave soldering YS-450Y / YS-450YT

High Quality Integrated selective wave soldering YS-320Y/ YS-320YT