1.High heat energy, low energy consumption, high power motor matching wind wheel, theoretical and practical verifification; under the same conditions set, can ensure the small and large components to achieve the minimum heat absorption difffference, and achieve the best thermal balance;

2.The latest thermal insulation technology and the new furnace structure design can effffectively reduce the furnace surface temperature and reduce the heat loss;

3.Imported PLC program controller, stable and reliable performance, high precision of temperature control and curve repetition;

4.Double-sided guide rail with special hardening treatment, strong and durable, repeatable use, cost saving up to 50%;

5.Online maintenance of rosin recycling system, modular design, convenient maintenance, reduce maintenance time;

6.Patented hot air system, hot air convection conduction more effiffifficient, faster heat compensation;

7.Built-in real-time monitoring system of furnace temperature, which can automatically generate furnace temperature curve (option);

8.Intelligent data can be traced and uploaded to MES system.

| U series reflow oven main specifications | |||

| Model No | YSL-808UA/YSL-808UN | YSL-810UA/YSL-810UN | YSL-812UA/YSL-812UN |

| Heating System | |||

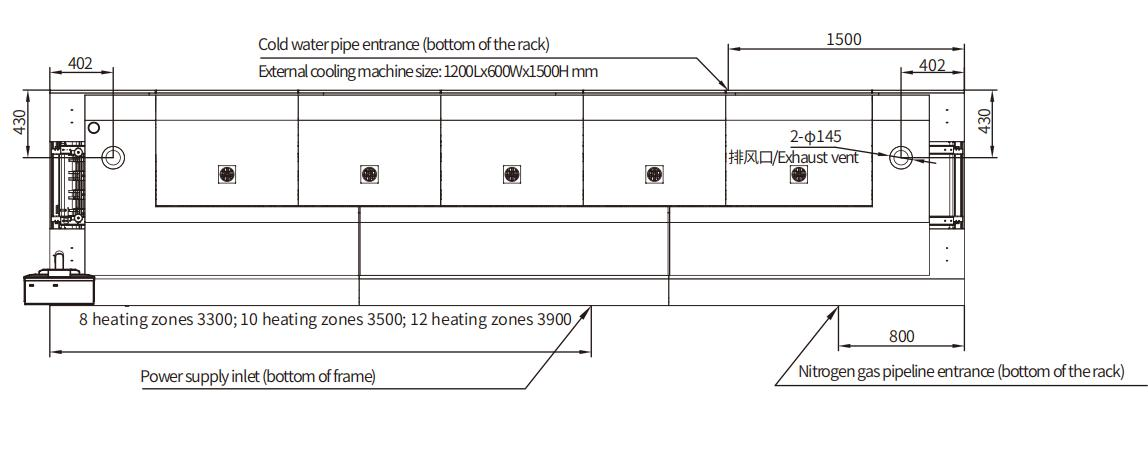

| Heating Zone | 8 heating zones,16 heating modules | 10 heating zones,20 heating modules | 12 heating zones,24 heating modules |

| Heating Length | 2950mm | 3670mm | 4390mm |

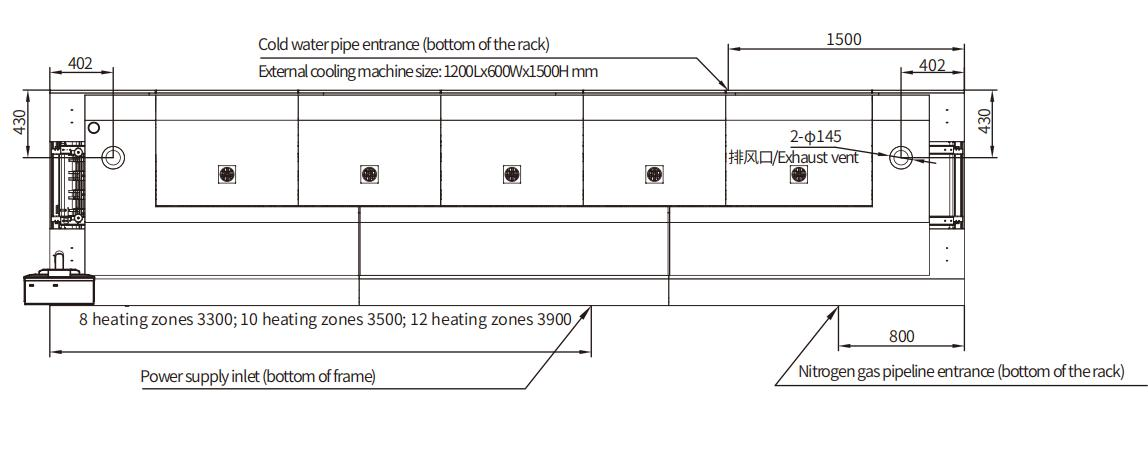

| Cooling Type | Three cooling zones:forced air cooling/water cooling | ||

| Outlet Exhaust Diameter,valume | 2-φ145,Exhaust demand 15-20m³/min*2 | ||

| Conveyor System | |||

| Product Width | min50mm-max400mm | ||

| Conveying Direction | L→R,R→L | ||

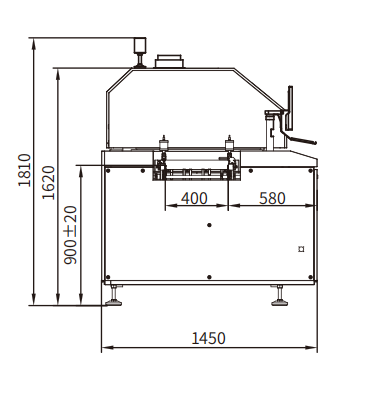

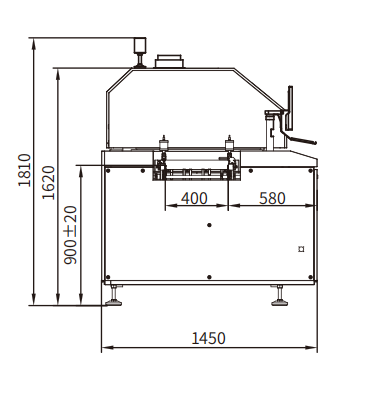

| Conveyor belt height | 900±20mm | ||

| Fixed Rail Side | |||

| Conveyor Type | Chain + mesh with synchronous conveying | ||

| Cmponent Height | +30mm-25mm/Clearance above 30mm,Clearance below 25mm | ||

| Conveying Speed | 300mm-2000mm/min | ||

| Control System | |||

| Power Supply | AC30 5W 380V 50/60HZ | ||

| Total Power | 57KW | 71KW | 89KW |

| Start UP Power | 30KW | 35KW | 40KW |

| Running Power | 7.5KW | 9.5KW | 11.5KW |

| Temperature Range | Room temperature 320℃ | ||

| Control type | PC+PLC Control System | ||

| Rail Width Adjusting Mode | Electric+Manual | ||

| Temp Control Accuracy | ±1℃ | ||

| PCB Temp Deviation | ±1℃ | ||

| Data Storage | Process Data and status record | ||

| Power Outage Protection | Equipped with UPS | ||

| Operation Interface | Windows Chinese simplified,English online free switching | ||

| General | |||

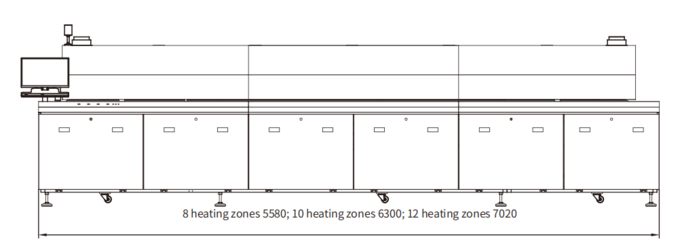

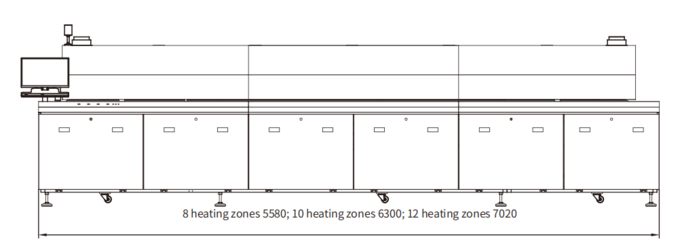

| Dimension(L*W*H) | 5580*1450*1620mm | 6300*1450*1620mm | 7020*1450*1620mm |

| Weight | 2300-2500KG | 2700-2900KG | 3100-3300KG |

| Color | Bright wrinkled white | ||

Technical requirements:

1,the customer to install control valve to control the import and export of the exhaust volume up to 145; .

2, each up to 145 entrance hole exhaust volume control in 15-20M³/min;

3, the main power supply: 3 380V diameter AC fifive wire, the main power line diameter of more than 35mm².

Modular structure for easy cleaning and maintenance. The front and rear air return design can effectively prevent the influence of airflow between the temperature zones and ensure accurate temperature control. Long life high performance hot air motor. Inverter control, hot air motor can be adjusted at high speed.

Manual + electric width adjustment structure design, equipped with emergency manual transmission structure to prevent power failure from burning out the PCB in the chamber

High stability control system with powerful functions

Special width adjustment and transmission structure design ensures stable and reliable PCB transmission, and the chain adopts anti-jamming plate chain.

1.High heat energy, low energy consumption, high power motor matching wind wheel, theoretical and practical verifification; under the same conditions set, can ensure the small and large components to achieve the minimum heat absorption difffference, and achieve the best thermal balance;

2.The latest thermal insulation technology and the new furnace structure design can effffectively reduce the furnace surface temperature and reduce the heat loss;

3.Imported PLC program controller, stable and reliable performance, high precision of temperature control and curve repetition;

4.Double-sided guide rail with special hardening treatment, strong and durable, repeatable use, cost saving up to 50%;

5.Online maintenance of rosin recycling system, modular design, convenient maintenance, reduce maintenance time;

6.Patented hot air system, hot air convection conduction more effiffifficient, faster heat compensation;

7.Built-in real-time monitoring system of furnace temperature, which can automatically generate furnace temperature curve (option);

8.Intelligent data can be traced and uploaded to MES system.

| U series reflow oven main specifications | |||

| Model No | YSL-808UA/YSL-808UN | YSL-810UA/YSL-810UN | YSL-812UA/YSL-812UN |

| Heating System | |||

| Heating Zone | 8 heating zones,16 heating modules | 10 heating zones,20 heating modules | 12 heating zones,24 heating modules |

| Heating Length | 2950mm | 3670mm | 4390mm |

| Cooling Type | Three cooling zones:forced air cooling/water cooling | ||

| Outlet Exhaust Diameter,valume | 2-φ145,Exhaust demand 15-20m³/min*2 | ||

| Conveyor System | |||

| Product Width | min50mm-max400mm | ||

| Conveying Direction | L→R,R→L | ||

| Conveyor belt height | 900±20mm | ||

| Fixed Rail Side | |||

| Conveyor Type | Chain + mesh with synchronous conveying | ||

| Cmponent Height | +30mm-25mm/Clearance above 30mm,Clearance below 25mm | ||

| Conveying Speed | 300mm-2000mm/min | ||

| Control System | |||

| Power Supply | AC30 5W 380V 50/60HZ | ||

| Total Power | 57KW | 71KW | 89KW |

| Start UP Power | 30KW | 35KW | 40KW |

| Running Power | 7.5KW | 9.5KW | 11.5KW |

| Temperature Range | Room temperature 320℃ | ||

| Control type | PC+PLC Control System | ||

| Rail Width Adjusting Mode | Electric+Manual | ||

| Temp Control Accuracy | ±1℃ | ||

| PCB Temp Deviation | ±1℃ | ||

| Data Storage | Process Data and status record | ||

| Power Outage Protection | Equipped with UPS | ||

| Operation Interface | Windows Chinese simplified,English online free switching | ||

| General | |||

| Dimension(L*W*H) | 5580*1450*1620mm | 6300*1450*1620mm | 7020*1450*1620mm |

| Weight | 2300-2500KG | 2700-2900KG | 3100-3300KG |

| Color | Bright wrinkled white | ||

Technical requirements:

1,the customer to install control valve to control the import and export of the exhaust volume up to 145; .

2, each up to 145 entrance hole exhaust volume control in 15-20M³/min;

3, the main power supply: 3 380V diameter AC fifive wire, the main power line diameter of more than 35mm².

Modular structure for easy cleaning and maintenance. The front and rear air return design can effectively prevent the influence of airflow between the temperature zones and ensure accurate temperature control. Long life high performance hot air motor. Inverter control, hot air motor can be adjusted at high speed.

Manual + electric width adjustment structure design, equipped with emergency manual transmission structure to prevent power failure from burning out the PCB in the chamber

High stability control system with powerful functions

Special width adjustment and transmission structure design ensures stable and reliable PCB transmission, and the chain adopts anti-jamming plate chain.

High Quality 3D laser marking machine For SMT Production Line YSL-3D-F30CY/50CY/100CY/ 200/CY

High Quality In-line flight marker For SMT Production Line YSL-F20CY/F30CY/F50CY

High Quality Pulse laser welding machine For SMT Production Line

High Quality Ultraviolet laser marking machine For SMT Production Line

High Quality Multi-function automatic laser welding machine For SMT Production Line

High Quality Fiber Laser Marking Machine For SMT Production Line

Full pneumatic steel mesh cleaning machine YSL-600 L1000*W700*H1730( mm )

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Environmentally Friendly Water-Based Online PCBA Cleaning Machine YSL-600-500

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Split selective wave soldering machine YS-320S For SMT Production LIine

High Quality Desktop selective wave soldering YS-E320 For SMT Production LIine

High Quality Integrated selective wave soldering YS-450Y / YS-450YT

High Quality Integrated selective wave soldering YS-320Y/ YS-320YT