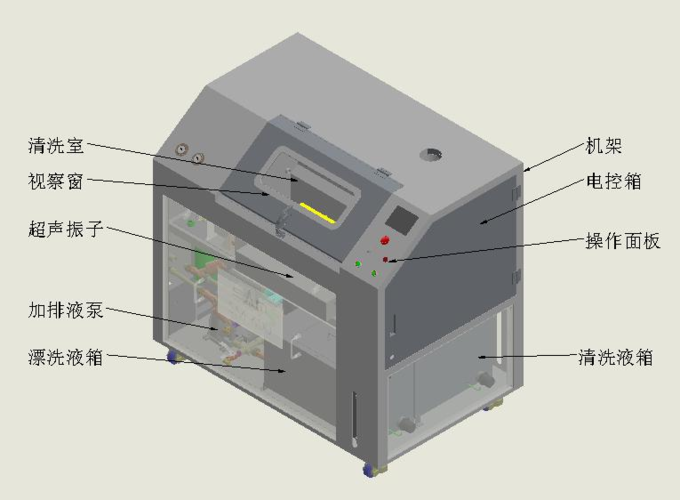

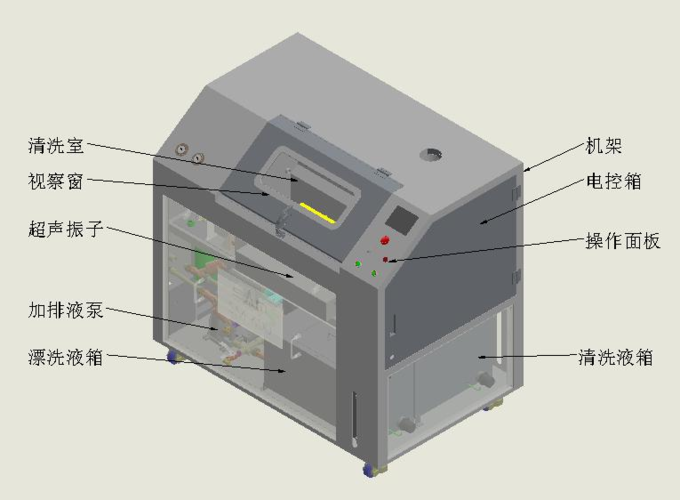

The equipment is used for scraper cleaning of printing press, such as residual solder paste, dust cleaning.

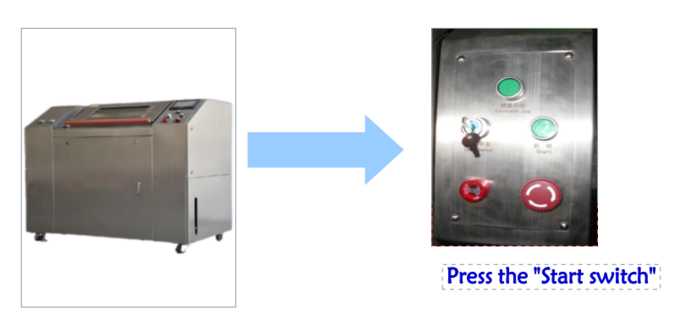

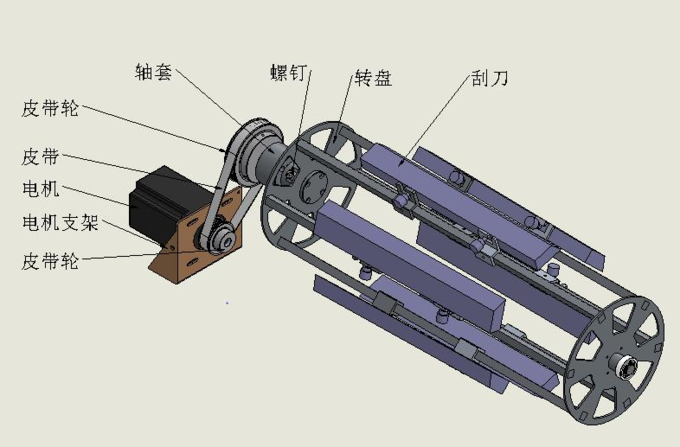

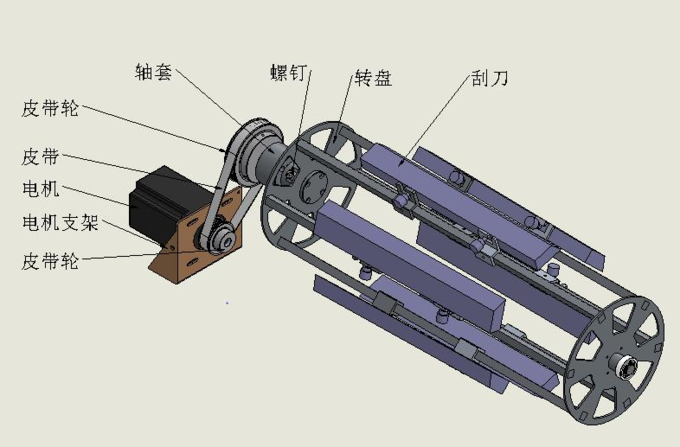

The "scraper cleaning machine" uses the scraper to rotate in the rotating basket and is cleaned by high pressure spray, ultrasonic cleaning, rolling rinsing, large flow fan hot air drying and other technologies to ensure the cleaning effect.

The use of alcohol liquids is prohibited. If the user uses alcohol liquids without permission and causes safety accidents, the manufacturer has nothing to do with it.

Scope of application(Printing scraper)

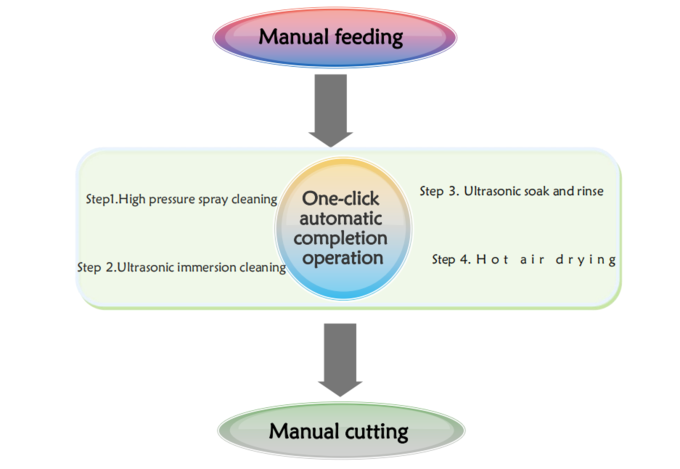

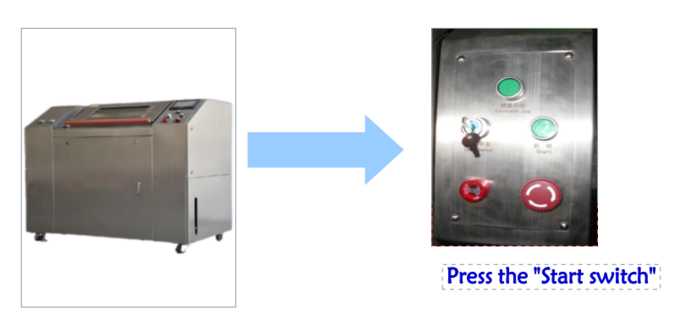

One-button operation, the whole cleaning process is fully automatic, automatic adding and discharging of washing liquid without manual intervention. Equipment low energy consumption, low noise, no pollution, energy saving and environmental protection, the whole stainless steel structure, small footprint.

The open state of the machine cover has protection function and cannot be started.

All the outlet of the liquid tank is equipped with a filter screen to prevent impurities from entering and protect the pump.

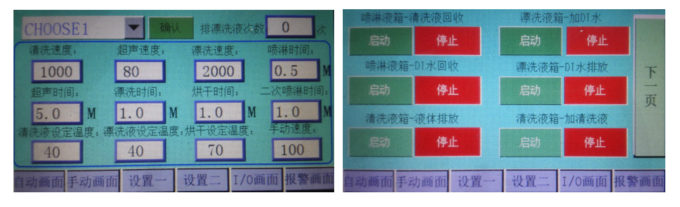

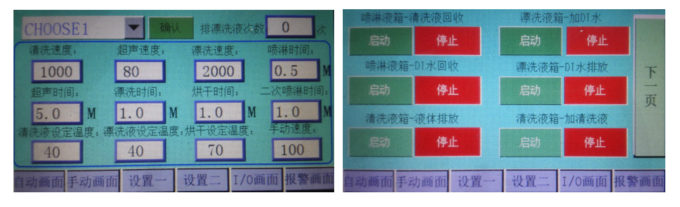

Cleaning, rinsing, air cutting, drying function in one. The time and speed of adding and discharging liquid, cleaning and rinsing can be set through the man-machine interface.

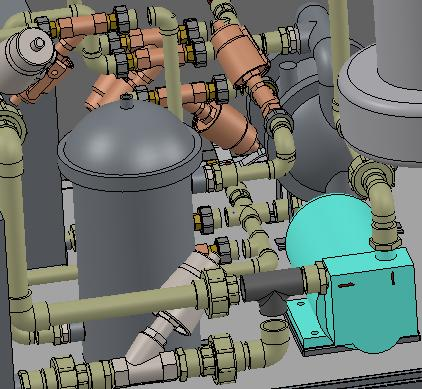

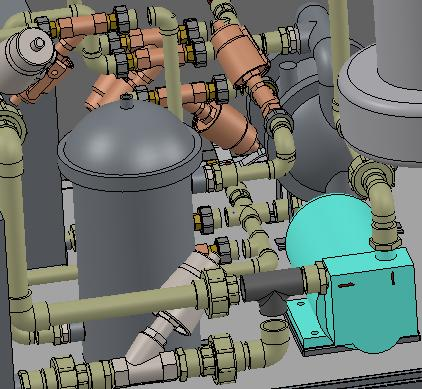

Imported PPH pipeline maintenance is simple

Solder paste recovery device

The nozzle pressure can be monitored during the cleaning process to ensure the cleaning effect.

| Model | YSL-680 |

| Size of equipment | 1400*900*1300 |

| Working basket diameter | 200mm |

| Maximum length of scraper | 600mm |

| Work basket load | 20KG |

| Gas pressure range | 0.4-0.6Mpa |

| Tank capacity | 60L |

| Pressure of spray | 0.15-0.3Mpa |

| Maximum power | 18KW |

| Voltage/frequency | 380V/50HZ |

| Recommended cleaning agent | Water based cleaning agentYSL-6001 |

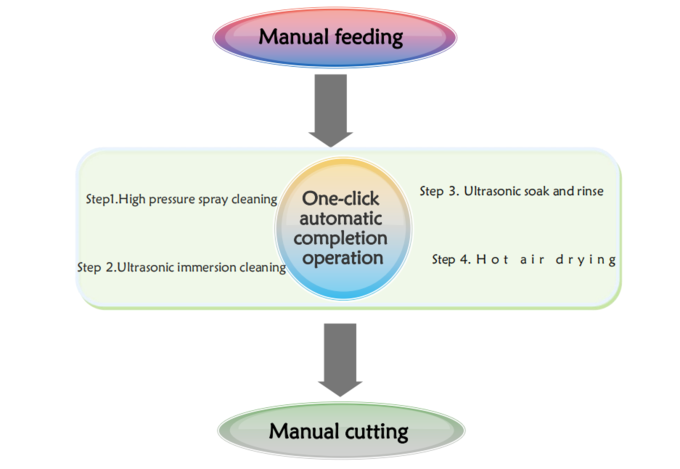

Cleaning: The cleaning process usually uses water - based cleaning solution, which is added externally. The liquid must be heated by a heater prior to cleaning operations to enhance cleaning capacity. Set the cleaning time on the touch screen. During cleaning, the high pressure water flow generated by the water pump is used to peel all the residual solder paste on the scraper to achieve the purpose of chemical cleaning. The peeled solder paste is filtered out through the bag filter device for recycling, so that the cleaning liquid recycling, while extending the life cycle of the cleaning liquid. Make the cleaning part dry without residue. The permanent combination of pollutants will not lead to the gradual reduction of the effective ingredients in the solution and shorten the service life, safe and reliable after cleaning.

Rinsing: The rinsing process uses water as the rinsing solution, which is added from an external pipe. Set the rinse time on the touch screen. When rinsing, the pressure produced by the water pump is used to shock the liquid residual substance off the fixture surface. The stripped pollutants are filtered out through the filter device to avoid secondary pollution and ensure the cleaning effect.

Drying: The drying process is to dry a small amount of water and water gas taken out by the scraper from the rinsing tank by using the high temperature and circulating hot air generated by the heater. In the process of wind flow, the heater will heat the wind quickly. When the hot air blows to the fixture surface, the circulating hot air speeds up the evaporation of the liquid. Remove moisture and moisture from the tool, thus achieving the purpose of drying.

Advantage:

1. Automatic filling and draining, rinsing function

Compared with similar products of other brands, the equipment has added automatic drainage system, rinsing function, so that the operator is more simple and convenient.

2. Tin paste recovery

As there is too much solder paste on the scraper, a washable stainless steel bag filter is specially designed to recover solder paste. Compared with the traditional disposable filter element, it greatly reduces the cost of consumables.

3. Pipe material

Imported PPH pipe material, using hot melt welding, can resist strong acid and alkali, to ensure the long-term use of no leakage. Relative to the stainless steel pipe maintenance, maintenance, replacement, more convenient and simple.

Return on investment

1. Save labor

2. The service life of the scraper is extended

3. Environmental protection and pollution-free, prevent chemical damage to the human body

1. How many scrapers can you fit?

Scraper size (mm) : 250-600

Display quantity (handfuls) : 6

2. How long does it take?

According to the different curing degree of the solder paste of the scraper, the cleaning time will be different. The following empirical data can be used for reference:

| Cleaning time | (Theoretical setting time) |

| Time of spray | 1-3min |

| Ultrasonic cleaning time | 3-8min |

| Second spray time | 2-5min |

| Rinse time | 1-3min |

| Drying time | 3-7min |

The equipment is used for scraper cleaning of printing press, such as residual solder paste, dust cleaning.

The "scraper cleaning machine" uses the scraper to rotate in the rotating basket and is cleaned by high pressure spray, ultrasonic cleaning, rolling rinsing, large flow fan hot air drying and other technologies to ensure the cleaning effect.

The use of alcohol liquids is prohibited. If the user uses alcohol liquids without permission and causes safety accidents, the manufacturer has nothing to do with it.

Scope of application(Printing scraper)

One-button operation, the whole cleaning process is fully automatic, automatic adding and discharging of washing liquid without manual intervention. Equipment low energy consumption, low noise, no pollution, energy saving and environmental protection, the whole stainless steel structure, small footprint.

The open state of the machine cover has protection function and cannot be started.

All the outlet of the liquid tank is equipped with a filter screen to prevent impurities from entering and protect the pump.

Cleaning, rinsing, air cutting, drying function in one. The time and speed of adding and discharging liquid, cleaning and rinsing can be set through the man-machine interface.

Imported PPH pipeline maintenance is simple

Solder paste recovery device

The nozzle pressure can be monitored during the cleaning process to ensure the cleaning effect.

| Model | YSL-680 |

| Size of equipment | 1400*900*1300 |

| Working basket diameter | 200mm |

| Maximum length of scraper | 600mm |

| Work basket load | 20KG |

| Gas pressure range | 0.4-0.6Mpa |

| Tank capacity | 60L |

| Pressure of spray | 0.15-0.3Mpa |

| Maximum power | 18KW |

| Voltage/frequency | 380V/50HZ |

| Recommended cleaning agent | Water based cleaning agentYSL-6001 |

Cleaning: The cleaning process usually uses water - based cleaning solution, which is added externally. The liquid must be heated by a heater prior to cleaning operations to enhance cleaning capacity. Set the cleaning time on the touch screen. During cleaning, the high pressure water flow generated by the water pump is used to peel all the residual solder paste on the scraper to achieve the purpose of chemical cleaning. The peeled solder paste is filtered out through the bag filter device for recycling, so that the cleaning liquid recycling, while extending the life cycle of the cleaning liquid. Make the cleaning part dry without residue. The permanent combination of pollutants will not lead to the gradual reduction of the effective ingredients in the solution and shorten the service life, safe and reliable after cleaning.

Rinsing: The rinsing process uses water as the rinsing solution, which is added from an external pipe. Set the rinse time on the touch screen. When rinsing, the pressure produced by the water pump is used to shock the liquid residual substance off the fixture surface. The stripped pollutants are filtered out through the filter device to avoid secondary pollution and ensure the cleaning effect.

Drying: The drying process is to dry a small amount of water and water gas taken out by the scraper from the rinsing tank by using the high temperature and circulating hot air generated by the heater. In the process of wind flow, the heater will heat the wind quickly. When the hot air blows to the fixture surface, the circulating hot air speeds up the evaporation of the liquid. Remove moisture and moisture from the tool, thus achieving the purpose of drying.

Advantage:

1. Automatic filling and draining, rinsing function

Compared with similar products of other brands, the equipment has added automatic drainage system, rinsing function, so that the operator is more simple and convenient.

2. Tin paste recovery

As there is too much solder paste on the scraper, a washable stainless steel bag filter is specially designed to recover solder paste. Compared with the traditional disposable filter element, it greatly reduces the cost of consumables.

3. Pipe material

Imported PPH pipe material, using hot melt welding, can resist strong acid and alkali, to ensure the long-term use of no leakage. Relative to the stainless steel pipe maintenance, maintenance, replacement, more convenient and simple.

Return on investment

1. Save labor

2. The service life of the scraper is extended

3. Environmental protection and pollution-free, prevent chemical damage to the human body

1. How many scrapers can you fit?

Scraper size (mm) : 250-600

Display quantity (handfuls) : 6

2. How long does it take?

According to the different curing degree of the solder paste of the scraper, the cleaning time will be different. The following empirical data can be used for reference:

| Cleaning time | (Theoretical setting time) |

| Time of spray | 1-3min |

| Ultrasonic cleaning time | 3-8min |

| Second spray time | 2-5min |

| Rinse time | 1-3min |

| Drying time | 3-7min |

High Quality 3D laser marking machine For SMT Production Line YSL-3D-F30CY/50CY/100CY/ 200/CY

High Quality In-line flight marker For SMT Production Line YSL-F20CY/F30CY/F50CY

High Quality Pulse laser welding machine For SMT Production Line

High Quality Ultraviolet laser marking machine For SMT Production Line

High Quality Multi-function automatic laser welding machine For SMT Production Line

High Quality Fiber Laser Marking Machine For SMT Production Line

Full pneumatic steel mesh cleaning machine YSL-600 L1000*W700*H1730( mm )

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Environmentally Friendly Water-Based Online PCBA Cleaning Machine YSL-600-500

High Efficiency Split selective sprayer YS-320F For SMT Production LIine

High Quality Split selective wave soldering machine YS-320S For SMT Production LIine

High Quality Desktop selective wave soldering YS-E320 For SMT Production LIine

High Quality Integrated selective wave soldering YS-450Y / YS-450YT

High Quality Integrated selective wave soldering YS-320Y/ YS-320YT